Adipic acid dihyhrazide

Brand : Linking chemical

Product origin : China

Delivery time : 15-20days

Supply capacity : 2000 tons a year

Adipic acid dihyhrazide and Diacetone Acrylamide are applied as cross-linking agent in water-based acrylic coatings, and also used as curing agent in epoxy resin. Adipic acide dihyhrazide has REACH certificate. And we now cooperate with DOW and BASF.

Adipic acid dihyhrazide APLICATIONS

1. Normal temperature water - based paint curing agent, used in room temperature crosslinking, in water-based acrylic resin system and Diacetone Acrylamide, High performance waterborne coatings. It can be used in wood lacquer, metal paint. building paint and concrete elastic coating.

2. PU polyurethane adhesive coating chain extender

3. Formaldehyde scavenger, Adipic acide dihyhrazide reacts with formaldehyde and prevents formaldehyde from evaporating into the air. applied to plywood, leather processing, etc.

4. Epoxy ester is used as a latent curing agent

5. Adipic acide dihyhrazide high temperature and epoxy resin reaction quickly, can also be used in powder coatings.

6. Improvement of plastics

7. Fiber processing

8. Stabilizers and crosslinking agents for fiber, emulsion and synthetic resins.

PRODUCT IDENTIFICATIONS | ||||

Chemicla name | Adipic acid dihyhrazide | |||

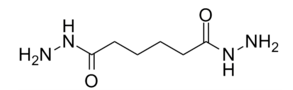

Chemical Structure |

| |||

Molecular formula | C6H14N4O2 | |||

Molecular Weight | 174.2 | |||

CAS NO. | 1071-93-8 | |||

EINECS NO. | 213-999-5 | |||

TSCA | On Inventory | |||

PRODUCT SPECIFICATIONS | ||||

Item | Unit | Specifications | Typical Result | |

Apearance | white powder | PASSEED | ||

Purity | wt% | 98min | 99.30 | |

Meilting point | degC | 177-183 | 182 | |

Drying loss | wt% | 0.5max | 0.30 | |

PHYSICAL PROPERTIES | ||||

Item | Unit | data | ||

Meilting point | deg C | 177-183 | ||

Solubility in water (30 deg C) | g/100g | 12.5 | ||

PROCESS CHARACTERISTICS | ||||

This production process has a strong continuity, no triwaste discharge, low energy consumption, stable product quality, especially the appearance of the product (approximate pure white), and almost no smell. Continuous process In addition to the intermittent production process, except reaction and crystallization drying process. the whole process adopts continuous production process. the production process is stable. the output consumption and the quality are stable and there is almost no batch difference. Automatic control The production process of this device realizes automatic control, automatic chain control of whole process. Quality control Using continuous extraction, distillation, evaporation and crystallization process,the products are almost white and tasteless,and the product quality is stable and easy to control because of the automatic continuous production process. Three waste Optimize the production process. Less three waste in the production process. | ||||

PACKING

20kgs in carton box or fibre drum

DELIVERY

Port:SHANGHAI, QINGDAO

Lead Time : Within 20 days after confirmed the order